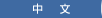

Seibu successfully developed the world's first CNC Wire Electrical Discharge Machine(W-EDM) in 1972.

Then, we released new model M series of high-speed, high-precision wire EDM and MM series with improved static accuracy in 2003,

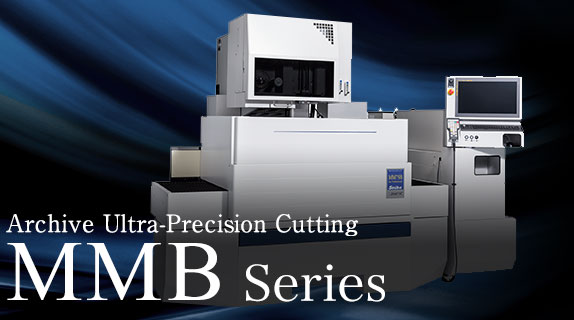

then released ultra-precision wire EDM “MP250S” in 2005.In 2009, SuperMM series was born as more sophisticated ultra-precision model.

Pitch accuracy of 2μm can be consistently achieved with SuperMM series that has traditional scraping technique “KISAGE”.

We are sure our customers will be very satisfied with Super MM series by the marvelous cost-benefit performance.

Professional Pefformance to Achieve Ultra-Precision Cutting

Traditional Technique "KISAGE"

MM series has achieved cutting accuracy in submicron and long term stable pitch accuracy.

Much Improved Cutting Accuracy

Can meet ultra-precision metal mold!

Operator can do cutting such as progressive plate cutting with confidence by use of the world’s top-class AWF.

Thermal Adjust 24 (Patent Pending)

This automatically corrects the displacement of wire vertical position due to the surrounding temperature change or effect of the heat by electric discharge.

This function can enhance the shape accuracy of product.

It is also possible to obtain better cutting accuracy without spending money ontemperature control facility.

MM35B

| Max. workpiece dimensions W×D×H | 650×550×190mm |

|---|---|

| Max.workpiece weight | 350kg |

| Axis travel range X×Y×Z | 350×250×200mm |

| Wire diameter | 0.07mm to 0.3mm dia.(φ0.2mm dia,is standard.) |

| Automatic wire feeding device | AWF-4 Equipped as standard |

| U-V axis travel U×V | ±60×±60mm |

| Max.taper angle | ±10° (190mm work thickness)(±45°/40mm: option) |

| Dimensions W×D×H | 1,370×1,785×1,990mm |

| Weight | 2,900kg |

MM50B

| Max. workpiece dimensions W×D×H | 800×650×270mm |

|---|---|

| Max.workpiece weight | 800kg |

| Axis travel range X×Y×Z | 500×350×280mm |

| Wire diameter | 0.07mm to 0.3mm dia.(φ0.2mm dia,is standard.) |

| Automatic wire feeding device | AWF-4 Equipped as standard |

| U-V axis travel U×V | ±60×±60mm |

| Max.taper angle | ±10° (270mm work thickness)(±45°/40mm: option) |

| Dimensions W×D×H | 1,680×1,915×2,070mm |

| Weight | 3,400kg |

MM75B

| Max. workpiece dimensions W×D×H | 900×700×220mm |

|---|---|

| Max.workpiece weight | 1,000kg |

| Axis travel range X×Y×Z | 750×500×280mm |

| Wire diameter | 0.07mm to 0.3mm dia.(φ0.2mm dia,is standard.) |

| Automatic wire feeding device | AWF-4 Equipped as standard |

| U-V axis travel U×V | ±60×±60mm |

| Max.taper angle | ±10° (270mm work thickness)(±45°/40mm: option) |

| Dimensions W×D×H | 2,280×2,200×2,170mm |

| Weight | 5,100kg |

*Max.submerged cutting depth is 250mm. Flush cutting available for work 220 to 270mm high.

Have a question?

Plese feel free to make an inquiry or request for brochures, etc.