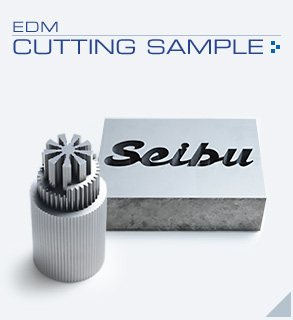

Precision wire EDM

Seibu made the world’s first CNC Wire Electric Discharge Machine (EDM) in 1972.

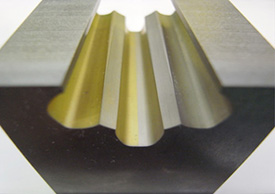

With a fine smooth motion, an electrode wire can cut metal as desired.

Our new, innovative technique for high-quality,

high-precision cutting is based on the pride in our craftsmanship that has made those

characteristics bywords in our company and representative of our products.

Seibu will continue to take that extra step in EDM manufacturing to provide

our valued customers with innovations and quality arising from the combination of traditional technique and advanced technologies.

Feature

For Ideal Non-Stop-Operation

This assures the automatic feeding at wire break point nearly 100%. (Patented in Japan, Europe, and the USA)

Top-class AWF (Automatic Wire Feeding Device) supports non-stop operation and greatly improves operation rate.

Traditional Technique "Kisage Hand Scraping"

Ultra-Precision Machines that had Kisage Hand Scraping are capable of achieving stable pitch cutting accuracy for many years.

Operability Improved from user's point of view

SS-Link

Check status when desired1. Check operation status at any time

2. Notifies cutting progress

Simple Attachment for start-hole drilling (SHM2)

EL Coating(Electrode Coating)

Coating is given to the cutting surface to prevent the life shortening of mold due to corrosion of cemented carbide.

The new technology can cut down the loss of cobalt by 70%, which extends the life of mold.

Core Stitch

The welded slug can be removed by tapping lightly.

So, you can drastically reduce the time for the cutting-off process. (97% Reduction!)

This is the industry’s first technology, and it will revolutionize the efficiency of wire EDM.

-

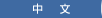

- Water Specification Ultra-precision wire EDM MEX15

- Ultra-precision wire EDM MM-UPseries

- Precision wire EDM M-HPseries

- Ultra-precision large-size wire EDM SuperMM80B

- High-precision wire EDM MM75B

- Precision wire EDM M75B

- Oil Specification Ultra-precision wire EDM MEX15

- Oil Specification Ultra-precision wire EDM M25LP

-

-

×

×