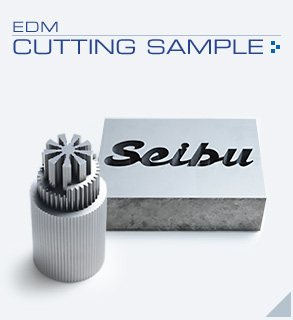

Seibu successfully developed the world's first CNC Wire Electrical Discharge Machine (W-EDM) in 1972.

Then, released new model MB series of higher-productivity, higher-precision wire EDM, and MMB and SuperMMB with further improved static accuracy.

In 2013, we released a long-waited oil-type (oil-working fluid) wire EDM [M25LP] developed based on a lot of experience and skills.

It works effectively for high precision machining of Tungsten Carbide compared to machining by the use of water-working fluid.

Therefore, [M25LP] will meet narrow pitch connector and LED parts in micro-fabrication using φ0.05 wire as well as the motor core mold of hybrid car for which we can expect demand increase from now.

X-Y same stroke, insulated quadrilateral table

Stable machining is achieved with high rigidity quadrilateral table.

Floating capacitance can be reduced to the limit by ceramic insulation, which makes the energy during machining stable.

Equipped with new type SF-7 (super finishing unit)

Achieved best surface roughness 0.2μmRz. (for Tungsten Carbide)

Stable pitch accuracy

Auto wire feeding device

Excellent feeding success rate for φ0.05 wire

M25LP

| Max.workpiece dimensions W×D×H | 270x270x100mm |

|---|---|

| Max.workpiece weight | 150kg |

| Axis travel range X×Y×Z | 250x250x200mm |

| Wire diameter | φ0.05~φ0.20mm(OP:φ0.05) |

| Automatic wire feeding device | AWF-4 Equipped as standard |

| U-V axis travel U×V | ±35x±35mm |

| Max.taper angle | ±10° (100mm work thickness) |

| Dimensions W×D×H | 1,770×2,040×2,018mm |

| Weight | 3,100kg |

Have a question?

Plese feel free to make an inquiry or request for brochures, etc.