Founded in 1927 as Seibu Electric Each path is creating a new future

Established as Seibu Electric and took over operations at the site of the Kyushu Factory of Toho Electric (Hakata-ku, Fukuoka city), which was an electric machinery factory of Toho Electric (currently Kyushu Electric Power Co., Inc.). Started Manufacture and repair of electrical machinery and devices (transformers, motors, generators) and electric meters.

Reorganized as Seibu Electric MFG. Co., Ltd. (capital: ¥180,000).

Moved electric equipment factory to Koga city in Fukuoka prefecture for increasing production of electric equipment for mining.

Moved company headquarters and factory and all other facilities to Koga city in Fukuoka prefecture.

Due to the downturn in the coal industry, focused efforts on developing new models to diversify out of electric equipment for mining. A light loader was developed.

Started production of motor blocks and valve controllers.

Completed valve controller mass-production factory.

Started production of machine tools (lathes) by adopting modification unit manufacturing technology, which was originally used for improving the performance of machine tools in company equipment.

Developed die sinking EDM and established large-scale machine tool factory.

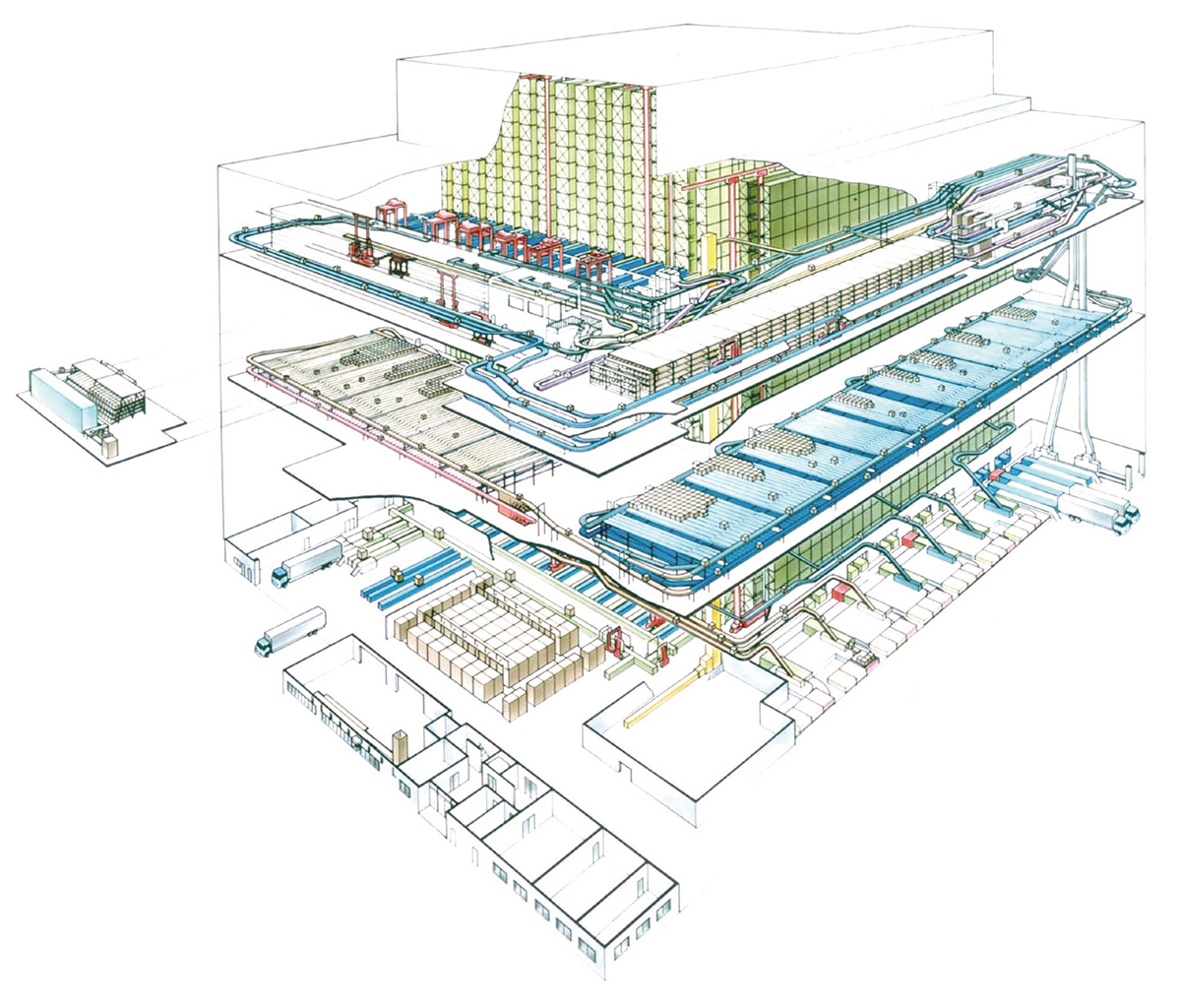

Developed automated warehousing system (monorail stacker crane).

Developed the world’s first CNC wire cut EDM.

Established Seiden Kosan Co., Ltd. for utilizing idle assets and operating and managing welfare facilities.

Developed high-precision, compact NC lathe.

Developed FMS Seibu DIO (Direct Input Output) System®.

Developed NC EDM.

Developed high-speed order picking system.

Developed the world’s first NC lead lathe.

Changed the corporate name to Seibu Electric & Machinery Co., Ltd.

Listed on the Fukuoka Stock Exchange (capital: ¥1,033,000,000).

Established new Tokyo Service Center in Ichikawa city, Chiba prefecture.

World's First CNC Wire EDM

High-Precision, Compact NC Lathe.

(Product Name: SNC)

Established office for design (with cafeteria).

Listed on the Second Section of the Osaka Securities Exchange (capital: ¥2,658,400,000).

Developed high-speed auto wire feeding device (AWF-3) for EDM.

Established Seibu Techno Service Inc. (currently Seibu Hitec Co.,

Ltd.) to more effectively use our skills in parts machining for

Seibu products.

Developed high-speed sorting equipment, EE sorter and roll-in/roll-out case automated warehousing system (RIO-S).

Developed pin-rack gate actuator (manual/automatic).

Developed submerged type wire EDMs (M500S, M350S, M750S)

Developed accumulation system by stack tray.

Developed automated warehousing system for libraries.

Developed Semflex® V series and Semflex® LP series.

Developed high-precision free-form grinding machine (SFG-28).

Established Seibu Paint Co., Ltd. for conducting the painting

operations of Seibu products.

Developed ultra-high-precision wire EDM (MP250S).

Listed on the Second Section of the Tokyo Stock Exchange.

Built new headquarters building and new factory.

Developed assort boomerang system.

Developed automated system for vault filled with urns.

Developed large-size chain gate driver.

Developed high-precision wire EDM (MM750S).

Developed Semflex® A series.

Developed ultra-high-precision wire EDM (SuperMM50A).

Formed business/capital alliance with Toyota Industries Corporation

for Distribution Equipment Business.

Developed multi-sorting RIO system.

Developed oil-type wire EDM (M25LP).

Developed horizontal floodwall gate actuator (Suikouden® HPM series).

Developed robot picking and sorting system.

Developed ultra-high-precision wire EDM (UltraMM50B).

Developed swing gate actuator (HGM series).

Built new multi-purpose factory.

Developed oil-type, ultra-high-precision wire EDM (MEX15).

Developed electric valve control for escort vessels.

MEX15 received the "Monozukuri Award from the Japan Society for

Precision Engineering".

Started valve control stock sales in Thailand.

Started supplying cranes to Toyota Industries Corporation as an OEM

supplier.

Developed fine picker C and cart case loader.

Acquired ISO 14001 certification for environmental management system.

Developed high-precision, large wire EDM (SuperMM80B).