Three businesses:Distribution equipment business, Industrial machine division, and Precision machine division

Seibu Electric was established in 1927 by taking over the operations of the Kyushu

Factory of Toho Electric, which served as a repair factory for Toho Electric (currently

Kyushu Electric Power Co., Inc.). Starting out in the repair and manufacture of

electrical devices and electric meters, we restructured into our current organization in

1939, and in June 1945, we moved our headquarters to its current location in Koga

city.

Since then, we have overcome numerous obstacles, and through tireless dedication to

product development and improvement, we have expanded our operations from the

manufacturing of coal mine electrical machinery to our diverse product lineups

today.

Our products contribute to higher productivity, streamlined logistics, higher

efficiency, energy-savings, and automation in a wide array of fields, including

automobiles, electrical equipment, precision machines, dies, petrochemistry, foodstuffs,

civil engineering and construction, shipbuilding, and more, enabling us to develop a

loyal customer base in Japan and abroad. Through cutting-edge technology and unrivaled

quality, we will continue to build greater trust with our customers.

-

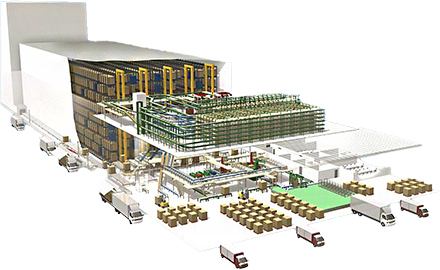

Distribution Equipment Business

Providing the Best Solution for Logistics

We believe that there is a unique solution for each customer. This is what drives us to propose and build an optimal logistics solution that is custom-tailored for each customer.

We are logistics professionals who first learn about the needs of our customers, analyze their problems, and then use our combined hardware and software technology to create space in any desired size or shape.Main ProductionAutomated warehousing systems/Factory automation systems/Automatic case picking systems/Piece picking systems/Conveyor and handling systems

-

Industrial Machine Division,Industrial Machine Business

Controlling the Valves of the World

For a half century, we have continued to provide the valve actuators and gate drivers that play an important role in guiding the water, electricity, gas, oil, and other energy sources that are essential in our lives, and we have largest market share in Japan. In recent years, we have taken up challenges in new fields by proposing system solutions that meet customer needs in response to demand for new installations and updates.

Main ProductsValve actuators/Gate actuators

-

Prerecision Machine Division,Industrial Machine Business

Pursuit of Precision and Accuracy and the Ultimate ing High Precision

In the Precision Machine Division, we are conducting production with the same attention to detail as handmade products, which have features unachievable in mass production.

This devotion has enabled us to develop machines capable of maintaining high precision over long periods of time. We have utilized our exclusive Seibu technology to develop wire EDMs that have earned a solid reputation for their pitch cutting accuracy, NC lathes capable of machining small precision parts, and grinding machines capable of free-form machining for providing customers with products that meet their accuracy and precision needs.Main ProductsUltra-precision and high-precision wire EDMs/High-precision, compact NC lathes/High-precision free-form grinding machines